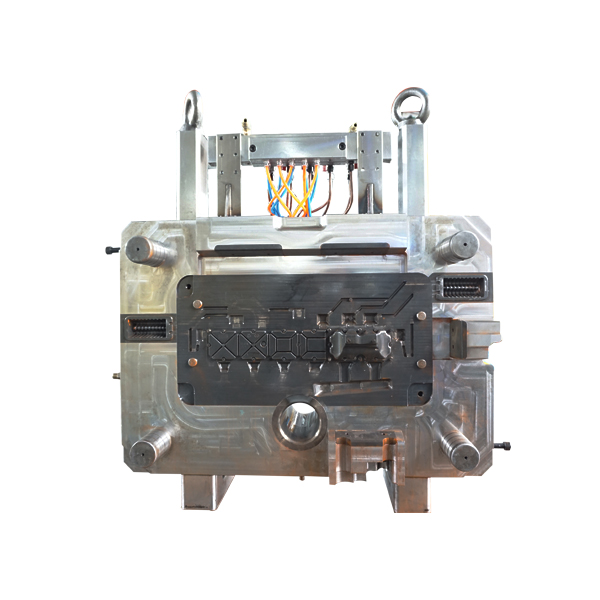

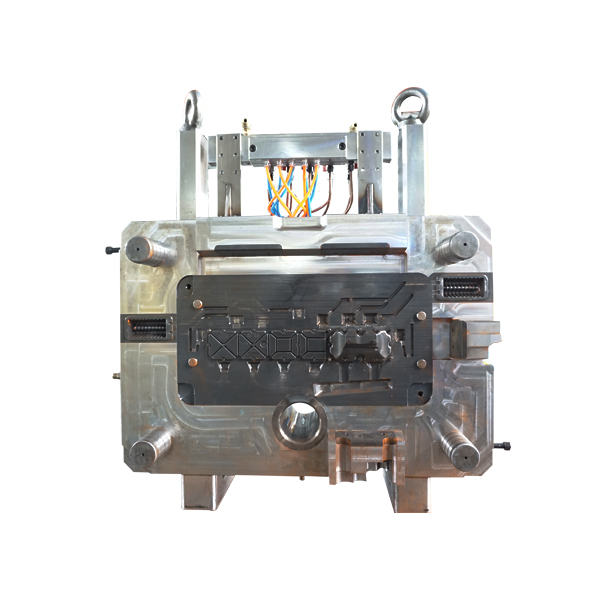

Die casting mould with material of H13, Die-var, DAC

adjustable ipad stand, tablet stand holders。

We also have a professional manufacturer integrating mould design and manufacture Team. We provide all kinds of precision die-casting moulds for automobile, LED street lamp, electric tool, gas appliance, textile machinery and other industries. We are an international famous company "Bosch", "Siemens", "continuous", Philips "GMB", "Panasonic", "TTI"..

We have established a modern enterprise management system. Relying on technological innovation and the concept of product refinement, the company is committed to becoming the front end of the industry, adhering to the quality principle of "zero defect" and the business policy of "survival by quality and development by reputation". It is one of the enterprises with strong comprehensive strength and rapid development in the "die casting die industry".

The development of an enterprise needs a good environment and opportunities, advanced management concepts and a hard-working staff. Our mould always adheres to the employment mechanism of "people-oriented, not stick to one pattern", providing talents with opportunities for full development and a stage to display their talents. The humanized management concept of "treat each other with sincerity and develop together" makes the cohesion of the enterprise continuously improve and has become the front-end of the industry for sustainable development.

For die Manufacturing we are using Megama Simulation system for DFM to choose the best way of material running . And during machining we use the high speed CNC machine to keep the die with high quality . After CNC machining we will make CMM inspection in the insert to confirm the machining is Ok or not . If machining is “Green” , we will go ahead for die assembly and make trail . Our First Trail Pass rate is about 50% with whole parts CMM report . After the trail we provide the samples to customer end with the CMM report for double checking . If all clear we make the die loading preparation , and delivery the dies to customer end .