ODM Extrusion Casting Process Quotes – All kinds of ODM Aluminum casting parts A380 ADC12 – Fangchen

adjustable ipad stand, tablet stand holders。

ODM Extrusion Casting Process Quotes – All kinds of ODM Aluminum casting parts A380 ADC12 – Fangchen Detail:

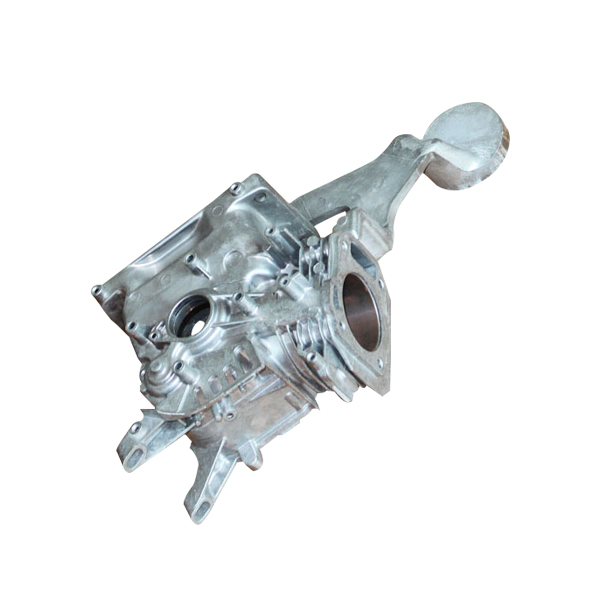

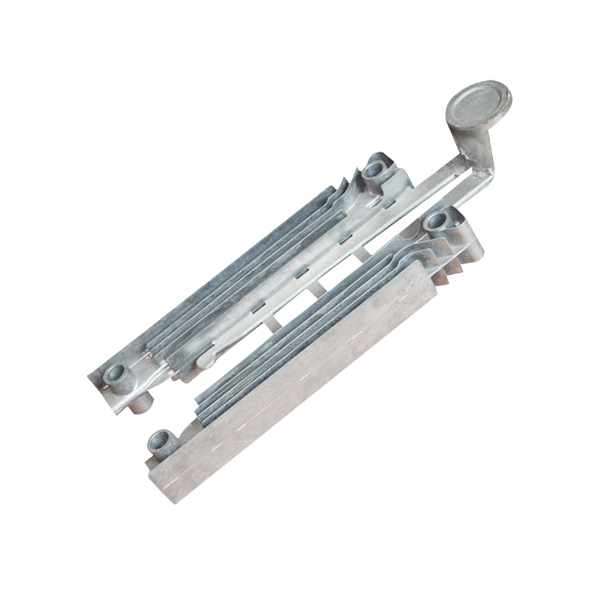

Please see our other products they are all customized parts we make the dies and make products for customers . All die-casting parts can be made by us with OEM as customer needs .

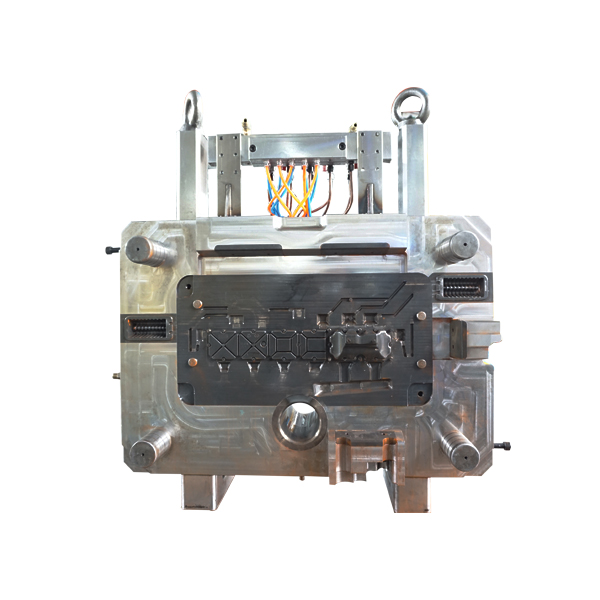

FANGCHEN has a professional and senior mold engineering team, providing optimal mold solution to customers based on their requirements in order to guarantee the products quality and mold life. We make the dies with MEGAMA Flow system . And after the simulation result get without any problem we go for die design .

We make die-casting by use our 200T-1250T machine.We can mass produce the parts with thin wall thickness as 1.0mm.We have accumulated rich experience on internal porosity and air tightness control in thick-wall die casting parts.

We use common materials are ADC12, A380 and A360. Other materials also can be customized based on client’s requirements . We have stable Material supplier in Shanghai and Jiangsu Province . Every time material get into our factory we will make the inspection of the material elements and leave record for future trail .

Our step to make the parts for customer as follow :

1-Get confirmation of the the customized Drawing

2-Start the design of the die

3-Make the die meanwhile analyze on the surface treatment

4-After Die ready make trail

5-Get the samples and make CMM inspection by following the Customized Drawing

6-After CMM report given “green light” , send samples to customer end for checking

7-After customer confirm the final parts , we will make the trail production like 100-1000 for first order

8-After customer confirm the trail production , we will follow customers order for future produce

Fangchen workers follow the steps strictly , every step can be trail if any problem on the products were find we can find out the problem and solve the problem in short time . And promise you to give you the best solutions for castings that you want to make in all kinds of fields .

What are the components of a casting?

There are six steps to this process:

Place the pattern in the sand to create the mold.

Design and sand are incorporated into the pouring system.

Remove the pattern.

Fill the cavity with molten metal.

Let the metal cool.

Break the sand mold and remove the casting.

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for ODM Extrusion Casting Process Quotes – All kinds of ODM Aluminum casting parts A380 ADC12 – Fangchen , The product will supply to all over the world, such as: Poland, Germany, New York, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!